Effect of heat treatment on steel

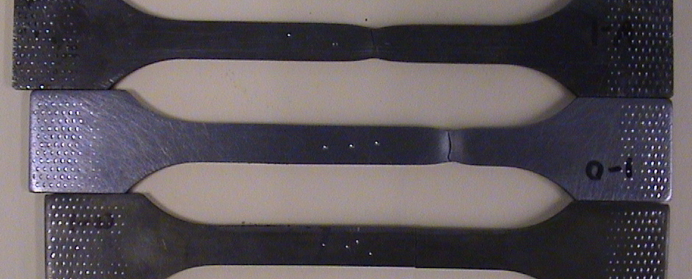

In this lab we work with one type of steel (usually 1050, which contains 0.5% carbon; sometimes 1010, which contains 0.1%). It is annealed at 850-900˚C to convert it to austenite (face-centered cubic crystal structure), then quenched into a bath of water or oil, or cooled in air. These treatments cause drastic differences in mechanical properties, as revealed in the video. The water-quenched sample contains a large amount of strong, brittle martensite, so it breaks after a small amount of stretching. Oil- and air-quenched samples are much more ductile. The difference in the final length of the samples is shown in the photo abo