Hercules Cement Plant

Stockertown, PA

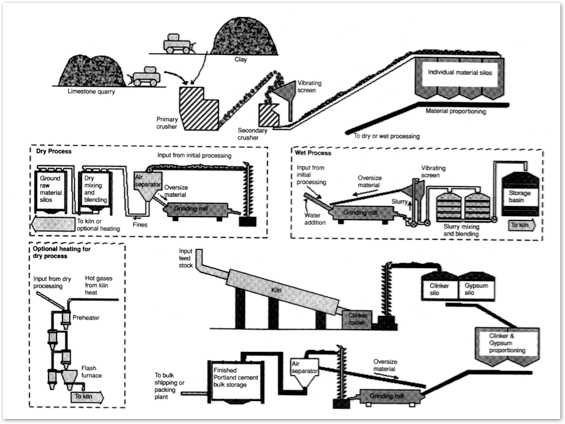

Each year the CEE364 class visits this cement plant, which makes one million tons of cement per year. The kiln, shown above, heats the raw materials to 1500˚C to convert limestone and clay into Portland Cement. The video shows some highlights of our tour. A diagram of the plant is shown below.

Hercules Cement Plant Layout

For the tour, we assemble in the testing lab (1), then go to the edge of the quarry (lower right) where we can sometimes see the blasting of the limestone. Huge trucks deliver the stone to a grinder that reduces it to baseball-size chunks that are carried up a conveyor into building 28. This is a dark eerie place where an automated system mixes the stone and pushes it into a hole, where it lands on another conveyor that takes it to the storage silos (25). We walk past the huge kiln (21) and enter the building (20) where the cement clinker is cooled and ground into powder. The cement powder is packed into bags (3) or stored in bulk in silos (4) from which it is loaded into trucks or railroad cars.

Cement Plant Schematic