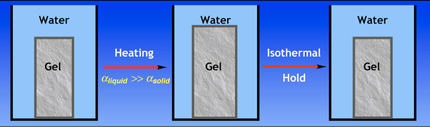

Before discovering the beam-bending technique, we developed a method for finding permeability from thermal expansion kinetics. Since the thermal expansion coefficient of liquids is high, when a saturated porous material is heated, the liquid expands more than the surrounding solid network. The liquid tends to flow out of the body, but if the permeability is low enough that it cannot escape as the temperature rises, then the liquid expands within the pores and stretches the solid phase. During an isothermal hold, the liquid drains from the pores and the solid shrinks to the size determined by its own thermal expansion coefficient. The rate of contraction during the hold depends on the permeability, as well as the elastic modulus, of the porous body. Therefore, if the modulus is known, the kinetics can be analyzed to extract the permeability. The following papers present the development of the theory for elastic gels, viscoelastic gels, and rigid viscoelastic bodies (for which the compressibility of the liquid and solid phases must be taken into account).

We had hoped to develop this method (which we now call thermopermeametry or TPA) into a convenient routine measurement for concrete, but it hasn’t worked out. First, the relaxation times are long when the sample is large, and secondly there is a problem with entrapped air. The pore pressure can relax by flowing into air voids, and the kinetics cannot be analyzed if the length of the flow path isn’t known.

Relevant papers:

Application to gels:

This paper demonstrates that the permeability obtained by this method is the same as by beam bending:

“Thermal Expansion of Gels: A Novel Method for Measuring Permeability”, G.W. Scherer, H. Hdach, and J. Phalippou, J. Non-Cryst. Solids, 130 (1991) 157-170; errata, J. Non-Cryst. Solids 194 (1996) 326

“Measuring permeability by the thermal expansion method for rigid or highly permeable gels”, G.W. Scherer, J. Sol-Gel Sci. Tech. 3 (1994) 31-40

“Thermal expansion of a viscoelastic gel”, G.W. Scherer, J. Sol-Gel Sci. Tech. 4 [3] (1995) 169-177

“Influence of viscoelasticity and permeability on the stress response of silica gel”, G.W. Scherer, Langmuir 12 [5] (1996) 1109-1116

“Thermal expansion of a gel layer on a rigid substrate”, G.W. Scherer, J. Non-Cryst. Solids 204 [2] (1996) 118-124

Application to cement paste:

“Thermal expansion kinetics: Method to measure permeability of cementitious materials: I, Theory”, G.W. Scherer, J. Am. Ceram. Soc. 83 [11] (2000) 2753-61; Erratum, J. Am. Ceram. Soc. 87 [8] (2004) 1609-1610

This study revealed that the permeability was increased by heating to quickly, owing to microcracking caused by high pore pressure:

“Thermal expansion kinetics: Method to measure permeability of cementitious materials: II, Application to hardened cement paste”, H. Ai, J.F. Young, and G.W. Scherer, J. Am. Ceram. Soc. 84 [2] (2001) 385-391; Erratum, J. Am. Ceram. Soc. 87 [8] (2004) 1611

“Characterization of Saturated Porous Bodies”, G.W. Scherer, Concr. Sci. Eng. 37 [265] (2004) 21-30

“Thermal expansion kinetics: Method to measure permeability of cementitious materials: III, Effect of viscoelasticity”, G.W. Scherer, J. Am. Ceram. Soc. 87 [8] (2004) 1509-1516

This study revealed that the thermal expansion of the pore liquid in cement paste is higher than bulk liquid (a result confirmed subsequently by direct dilatometric measurements):

“Evidence of anomalous thermal expansion of water in cement paste”, J.J. Valenza and G.W. Scherer, Cement Concr. Res. 35 (2005) 57-66

This paper describes a direct dilatometric technique that was used to confirm the high expansion of pore water in pores with diameters below ~15 nm:

“Thermal Expansion and Viscosity of Confined Liquids”, S. Xu, G.C. Simmons and G.W. Scherer, pp. 85-91 in Dynamics of Small Confining Systems, Mat. Res. Soc. Symp. Proc. Vol. 790, eds. J.T. Fourkas, P. Levitz, M. Urbakh, K.J. Wahl (Materials Res. Soc., Warrendale, 2004), P.6.8.1-7

“Thermal expansion kinetics: Method to measure permeability of cementitious materials: IV, Effect of thermal gradients”, J.P. Ciardullo, D.J. Sweeney, and G.W. Scherer, J. Am. Ceram. Soc. 88 [5] (2005) 1213–1221

Greg Simmons’ senior thesis research demonstrated that it could take weeks to remove air bubbles from mortar samples, so this method is impractical for routine measurements of concrete.